Author:HB Nonwoven MachineryFROM:Compressed Towel Machine Manufacturer TIME:2023-10-14

Introduction:

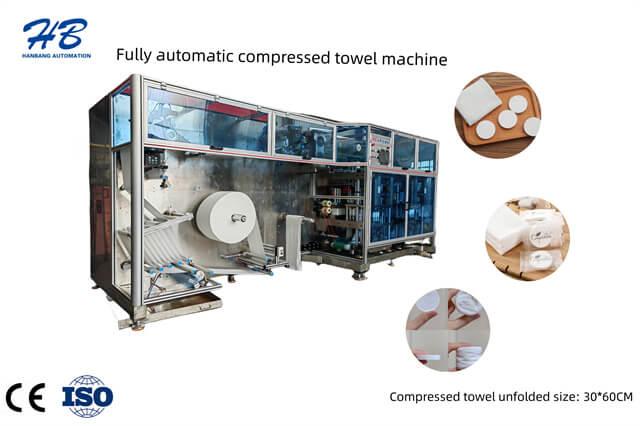

The Mini Compressed Bath Towel Machine is an innovative technological advancement in the hygiene industry. It offers unique features and benefits that revolutionize the way bath towels are produced and used. This article aims to highlight the technological aspects of this machine and its impact on the personal care sector.

The Mini Compressed Bath Towel Machine incorporates advanced automation technology, ensuring efficient and streamlined production. With its automated processes, this machine can compress and package bath towels rapidly, reducing production time and labor costs. The automation also guarantees consistent quality control, as it minimizes human errors in folding and sealing the towels.

The machine is equipped with sensors and software that enable precise towel compression, ensuring each towel is compressed uniformly. This feature enhances the overall appearance and presentation of the product, making it more attractive to customers. Additionally, the automated packaging system ensures neat and compact packaging, making it convenient for storage and transportation.

The Mini Compressed Bath Towel Machine offers a high degree of customization, allowing manufacturers to tailor towels to specific requirements. The machine can accommodate various towel sizes, thicknesses, and fabric types, providing flexibility to meet customer demands. This feature enables manufacturers to cater to different market segments and offer a diverse range of products.

Moreover, the machine's software allows for the customization of packaging designs and branding options. Manufacturers can incorporate their logos, colors, and other branding elements on the compressed towels and packaging, enhancing brand recognition and visibility. This customization capability gives businesses a competitive edge in the market and helps build a strong brand identity.

The Mini Compressed Bath Towel Machine promotes eco-friendly operations and sustainable practices. It utilizes energy-efficient mechanisms, optimizing power consumption during the towel compression process. This reduces energy wastage and lowers carbon emissions, contributing to a greener environment.

Furthermore, the machine encourages the use of biodegradable and recyclable packaging materials. Manufacturers can choose eco-friendly packaging options, such as compostable film or recycled paper, to minimize waste generation. By adopting such practices, the machine supports the global effort towards environmental conservation and sustainability.

Conclusion:

The Mini Compressed Bath Towel Machine represents a significant advancement in the hygiene industry, offering technological features that enhance efficiency, customization, and sustainability. Its automation capabilities ensure streamlined production processes, while customization options allow manufacturers to cater to diverse customer preferences. Additionally, the machine's eco-friendly operations contribute to a greener planet. With its numerous benefits, this machine is set to revolutionize the bath towel manufacturing sector and meet the evolving needs of consumers.