Quanzhou Hanbang Automation Equipment Co., Ltd. specializes in the production of non-woven fabric punching and embossing equipment (single/double-station unwinding, double-station rewinding), non-woven fabric three-dimensional embossing laminating machine

![]() Price: Negotiable

Price: Negotiable

![]() Model: HBJX-W1400-SD

Model: HBJX-W1400-SD

![]() Power: Three-phase, 380V, 50HZ. Total installed power:33KW

Power: Three-phase, 380V, 50HZ. Total installed power:33KW

![]() Finished Product Specifications: Width 75-1400mm, roll diameter 850mm

Finished Product Specifications: Width 75-1400mm, roll diameter 850mm

![]() Raw Material: Air-through nonwovens and spunbond nonwovens

Raw Material: Air-through nonwovens and spunbond nonwovens

![]() Speed: Design speed: 90M/min. Actual production speed: 50-85M/Min (according to mold pattern)

Speed: Design speed: 90M/min. Actual production speed: 50-85M/Min (according to mold pattern)

![]() Dimensions: length * width * height =6.0*2.8*2.5Mmeters (1400 model)

Dimensions: length * width * height =6.0*2.8*2.5Mmeters (1400 model)

![]() Qualified Rate: ≥98%

Qualified Rate: ≥98%

![]() Configuration: Full servo power single layer composite embossing machine configuration

Configuration: Full servo power single layer composite embossing machine configuration

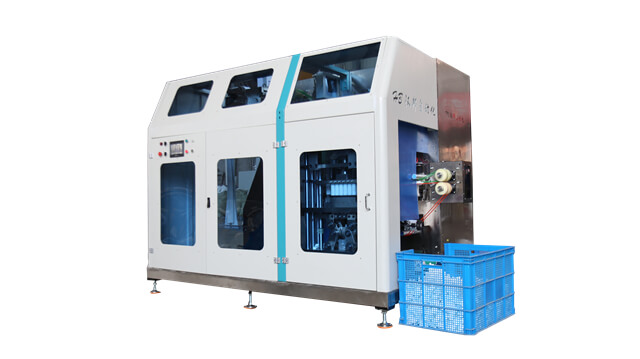

![]() Equipment Color: Rack metal silver aluminum alloy + gray and white sheet metal frame

Equipment Color: Rack metal silver aluminum alloy + gray and white sheet metal frame

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Working Voltage: 380V

Working Voltage: 380V

![]() Working Air Pressure: 6Bar

Working Air Pressure: 6Bar

![]() Temperature Range: 0℃-45℃

Temperature Range: 0℃-45℃

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

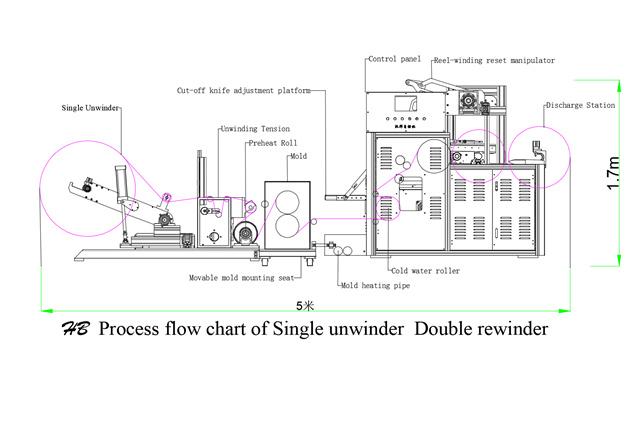

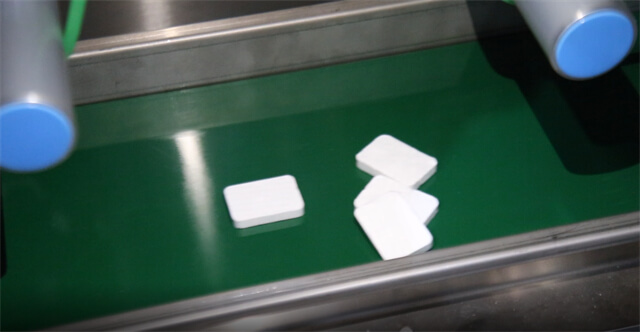

HBJX-W1400-SD series of new multi functional non-woven fabric perforation and embossing slitting and rewinding machines are mainly used for three-dimensional perforation and funnel-type perforation of non-woven fabrics or perforated films. The spunbond non-woven fabric produced has a strong three-dimensional hole pattern, is more beautiful, has higher quality, penetrates faster, does not repel liquid, is soft and dry, has a more comfortable skin-friendly feel, and can more effectively overcome the irritation of the skin. It has excellent air filtration effect and is more breathable and water-permeable. It is the first choice for surface fabrics of women's sanitary napkins, baby diapers and other products!

一、 in technical parameters

|

Device name/model |

Non-woven fabric perforating and embossing machine ( Single unwinding and double rewinding HBJX-W1400-SD) |

|

product |

Single layer hot air surface non-woven fabric 18-35g/m2 |

|

power supply |

Three-phase; 380V; 50Hz—Installed power: <=33KW (including mold heating) |

|

Design and production speed |

Design speed: 90M/min. Actual production speed: 50-85M/Min (according to mold pattern) |

|

Production material specifications |

The maximum rewinding and unwinding width is <=1400mm; the maximum rewinding and unwinding diameter: ф850mm; the minimum slitting width: 85mm. Maximum unwinding weight: 150KG, maximum rewinding weight 85KG. |

|

Overall dimensions (meters) |

(L*W*H):6.0*2.8*2.5M (for reference) |

|

Device color |

Rack metal silver aluminum alloy + gray and white sheet metal frame |

|

qualification rate |

Qualification rate ≧98% (excluding replacement joints and trimming materials) |

|

configuration plan |

Full servo power single layer composite embossing machine configuration |

Main features: This machine is a multi-functional equipment that can complete punching, embossing, slitting and rewinding at one time. Production process: raw materials on the mach...

2 machines, operated by one person, with a production width of 190mm, 60 meters per minute, and an actual output of 1.2-1.3 tons/machine in 12 hours....

The production of hot-air non-woven fabrics or spun-bonded non-woven fabrics has a strong three-dimensional hole shape, is more beautiful, has higher quality, penetrates faster, do...

The double unwinder and double rewinder embossing and perforating machine is very convenient to use. I only evaluated it after using it for a few days. I am satisfied with the quality and it looks very durable and perfect.Martin 2024-05-31

The level of customization this machine offers is impressive. It adapts to our specific needs without any hassle.Zachary 2024-06-05

Investing in this machine was one of the best decisions we've made for our business. It has increased our output and reduced waste.Josephine 2024-06-19