Author:HB Nonwoven MachineryFROM:Compressed Towel Machine Manufacturer TIME:2023-10-06

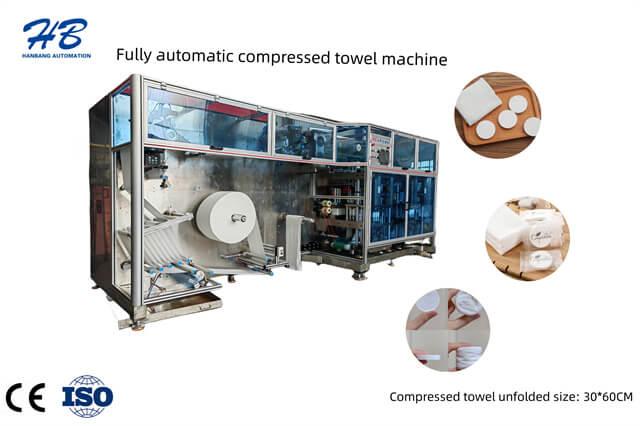

The nonwoven fabric industry has witnessed significant growth in recent years, especially in the production of compressed bath towels. These towels are not only convenient but also environmentally friendly, making them a popular choice among consumers. In this article, we will provide a step-by-step guide to using a nonwoven fabric compressed bath towel machine. Whether you are a manufacturer or simply curious about the production process, this guide will give you valuable insights into the fascinating world of nonwoven fabric bath towels.

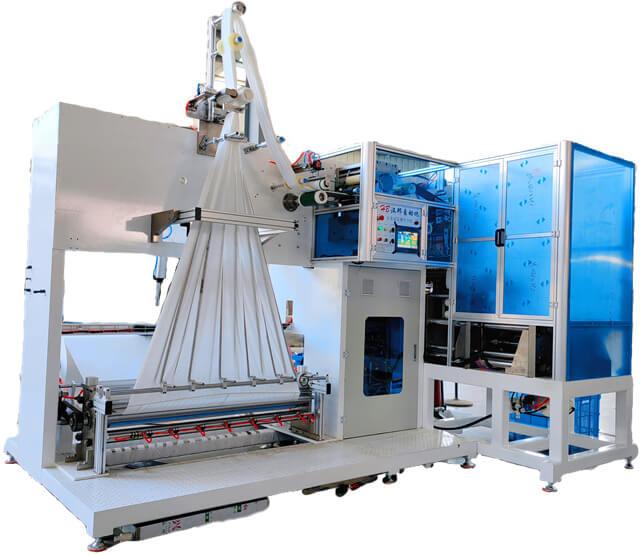

Before operating the nonwoven fabric compressed bath towel machine, it is crucial to ensure that all the raw materials are ready. These materials typically include nonwoven fabric rolls, water-soluble film rolls, and optional additives such as fragrance or lotion. Start by inspecting the quality of the nonwoven fabric rolls, checking for any defects or inconsistencies. Next, load the nonwoven fabric rolls onto the feeding shaft of the machine, ensuring a smooth and steady supply during the production process. Similarly, load the water-soluble film rolls onto their respective shafts, as they will serve as the outer layer of the compressed towel.

Once the raw materials are prepared, it's time to set up the machine parameters for optimal production. Begin by adjusting the tension of the nonwoven fabric rolls and water-soluble film rolls to ensure a balanced and uniform output. This can be done by using the tension adjustment knobs or levers on the machine. Additionally, set the desired length and width of the compressed towel using the control panel. It is important to note that different towel sizes may require adjustments in machine parameters, so always refer to the product specifications for accurate settings.

With the raw materials prepared and machine parameters set, it's time to start the production process. Begin by turning on the machine and allowing it to warm up for a few minutes. Once the machine reaches the desired temperature, it is ready for operation. Activate the feeding system to supply the nonwoven fabric and water-soluble film into the machine. The machine will automatically compress and bond the layers together, creating a sturdy and absorbent bath towel. Depending on the machine's capacity and speed, towels will be produced in a continuous stream or batches. Regularly monitor the production process to ensure quality control and address any issues that may arise.

In conclusion, using a nonwoven fabric compressed bath towel machine involves three main steps: preparing the raw materials, setting up the machine parameters, and operating the machine. By following this step-by-step guide, manufacturers can produce high-quality compressed bath towels efficiently and effectively. Consumers can enjoy the benefits of these convenient and eco-friendly towels, knowing the intricate process behind their creation. As the nonwoven fabric industry continues to evolve, innovations like the compressed bath towel machine will play a vital role in meeting the growing demands of consumers worldwide.