Author:HB Nonwoven MachineryFROM:Compressed Towel Machine Manufacturer TIME:2023-10-16

Unveiling the Technical Features of Nonwoven Fabric Compressed Bath Towel Machine

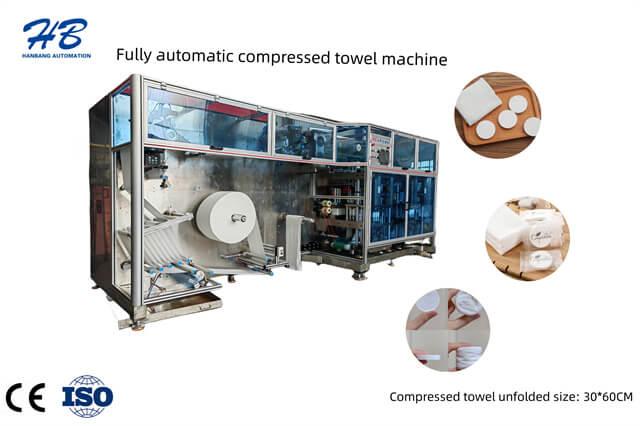

The nonwoven fabric compressed bath towel machine is a revolutionary innovation in the sanitary products industry. It combines advanced technology and materials to produce high-quality compressed bath towels that are portable, convenient, and eco-friendly. In this article, we will explore the technical features of this machine, highlighting its key components and functionalities.

At the core of the nonwoven fabric compressed bath towel machine lies the state-of-the-art nonwoven fabric technology. This technology utilizes specialized fibers, such as polyester, polypropylene, or viscose, which are mechanically or chemically bonded together to form a sheet of fabric. Unlike traditional woven fabrics, nonwoven fabrics are made directly from fibers, eliminating the need for spinning and weaving processes. This makes them more cost-effective and efficient to produce.

Furthermore, the nonwoven fabric used in the compressed bath towel machine undergoes a series of treatments to enhance its strength, softness, and absorption capacity. These treatments include hydroentanglement, thermal bonding, and chemical bonding. The resulting fabric is durable, lint-free, and skin-friendly, ensuring a comfortable and hygienic user experience.

The nonwoven fabric compressed bath towel machine consists of several key components that work together to produce compressed bath towels. The first component is the unwinding system, which unwinds the nonwoven fabric roll and feeds it into the machine. This system ensures a continuous and steady supply of fabric, minimizing downtime and improving productivity.

The second critical component is the compression system. This system compresses the nonwoven fabric sheet into a compact size, reducing its volume by up to 90%. The compression process involves the application of pressure and heat, which activates the bonding agents present in the fabric. As a result, the fabric retains its compressed form even after being unfolded, providing a refreshing and full-sized bath towel when wet.

Lastly, the cutting and folding system is responsible for cutting the compressed nonwoven fabric into individual towel sheets and neatly folding them. This system ensures precise cutting accuracy and uniform folding, resulting in perfectly packaged compressed bath towels ready for distribution and use. The machine also incorporates an automatic stacking system, which stacks the folded towels for convenient packaging and transportation.

The nonwoven fabric compressed bath towel machine is a game-changer in the hygiene products industry. Its advanced nonwoven fabric technology, coupled with efficient and precise functionalities, enables the production of high-quality compressed bath towels that are extremely portable and convenient. With its eco-friendly attributes and superior performance, this machine is paving the way for a new era of innovation in the sanitary products sector.