Author:HB Nonwoven MachineryFROM:Compressed Towel Machine Manufacturer TIME:2023-10-05

Step-by-Step Guide to Operating a Towel Making Machine

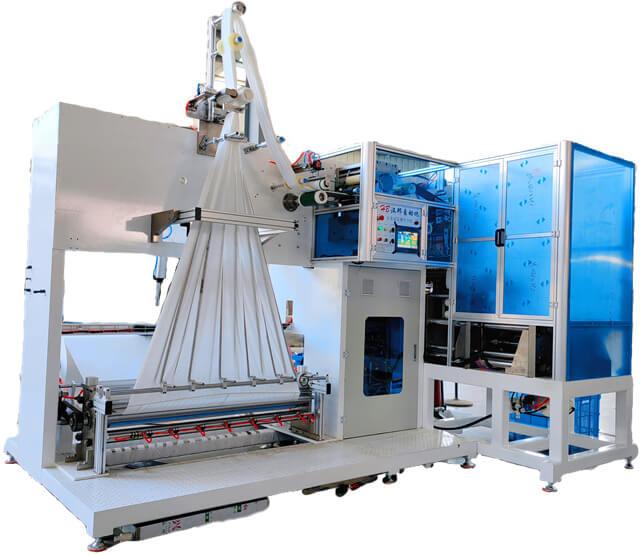

Operating a towel making machine in the textile industry requires a systematic approach to ensure efficient production and high-quality output. Whether you are a beginner or a seasoned professional, mastering the operational steps is crucial for running a successful towel manufacturing business. In this guide, we will provide you with a step-by-step breakdown of how to operate a towel making machine, highlighting key considerations and tips for each stage.

Before starting the production process, it is essential to properly prepare the towel making machine. This involves several important steps:

a) Cleaning and Maintenance: Begin by thoroughly cleaning the machine to remove any dust, dirt, or debris that may affect its performance. Regular maintenance checks should also be performed to ensure all parts are in good working condition.

b) Loading Raw Materials: Next, load the required raw materials, such as cotton or microfiber, into the machine's designated compartments. Follow the manufacturer's instructions for proper material placement and avoid overloading to prevent jams or malfunctions.

c) Adjusting Settings: Depending on the desired specifications for the towels, adjust the machine settings accordingly. This includes choosing the appropriate towel size, weight, absorbency, and any additional features like embossing or border designs.

Once the machine is prepared, it's time to begin the production process. Here are the steps to follow:

a) Powering On: Switch on the machine and ensure all the necessary power connections are secure and stable.

b) Testing the Machine: Before starting mass production, it is advisable to test the machine's functionality by producing a few trial towels. This allows you to fine-tune the settings and make any necessary adjustments before full-scale production.

c) Monitoring the Production Line: Once you are satisfied with the trial towels' quality, start the production line. Monitor the process closely, ensuring the smooth flow of materials, proper stitching, and consistent output. Keep an eye out for any warning signs of potential issues, such as thread breakage or irregularities in towel dimensions.

Producing high-quality towels involves careful finishing and rigorous quality control measures. Follow these steps:

a) Cutting and Trimming: After the towels are produced, cut and trim any excess threads or fabric to achieve a neat and uniform appearance.

b) Inspecting for Defects: Carry out a detailed inspection of each towel to identify any defects, such as stains, loose threads, or color inconsistencies. Remove any faulty towels from the batch to maintain high product standards.

c) Packaging: Finally, package the finished towels according to your preferred packaging standards. This may involve folding, tagging, and labeling each towel appropriately. Proper packaging helps protect the towels during transportation and enhances their overall presentation to customers.

Conclusion

Operating a towel making machine requires careful preparation, systematic steps, and keen attention to detail. By following this step-by-step guide, you can ensure the efficient production of high-quality towels. Remember to regularly maintain the machine, monitor the production process, and conduct thorough quality control checks. With practice and experience, you will gain proficiency in operating the towel making machine and achieve success in the textile industry.