This case study focuses on a customer from the Philippines who sought a non-woven embossing punching slitting and rewinding machine to enhance their manufacturing processes in the textile industry.

The customer, a leading manufacturer of non-woven fabrics, was looking to optimize their production line by investing in advanced machinery.

The customer, referred to as ABC Textiles, is a well-established company in the Philippines that specializes in the production of non-woven fabrics.

With a strong commitment to delivering high-quality products, they have successfully catered to a diverse range of industries such as medical, hygiene, and packaging.

1. Inefficient Production Line:

ABC Textiles faced challenges in their existing production line, which lacked automation and required excessive manual labor.

This led to lower productivity and increased production costs.

2. Quality Control:

The absence of an advanced slitting and rewinding machine made it difficult for ABC Textiles to maintain consistent quality standards for their non-woven fabrics.

3. Market Competition:

The customer faced fierce competition from both domestic and international manufacturers.

To stay competitive, ABC Textiles needed to upgrade their machinery and improve overall efficiency.

Non-Woven Embossing Punching Slitting and Rewinding Machine After thorough research and consultation with industry experts, ABC Textiles decided to invest in a non-woven embossing punching slitting and rewinding machine.

1. Automation:

The machine was equipped with automated systems for embossing, punching, slitting, and rewinding, reducing the reliance on manual labor and increasing productivity.

2. Customization:

The machine provided flexibility in terms of embossing patterns, punching designs, and slitting width, enabling ABC Textiles to cater to various customer requirements efficiently.

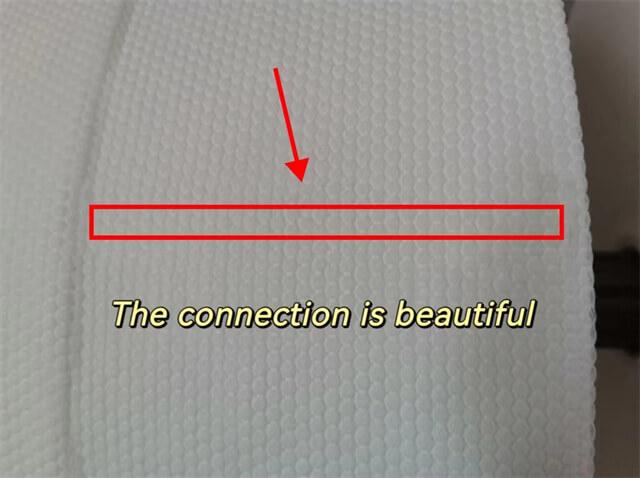

3. Quality Assurance:

The machine ensured precise cutting, consistent rewinding tension, and accurate embossing and punching, resulting in high-quality non-woven fabrics.

4. Cost Savings:

By streamlining the production process, reducing labor costs, and minimizing material wastage, ABC Textiles achieved significant cost savings.

5. Competitive Edge:

With the advanced capabilities of the machine, ABC Textiles gained a competitive edge by producing superior and customized non-woven fabrics.

1. Improved Efficiency: The non-woven embossing punching slitting and rewinding machine enabled ABC Textiles to increase their production capacity by 30%, effectively meeting growing market demands.

2. Enhanced Quality Control:

The machine ensured precise cutting, accurate embossing, and punching, leading to consistent quality standards across all their non-woven fabric products.

3. Cost Reduction:

By optimizing the production process and reducing manual labor, ABC Textiles experienced a 20% reduction in production costs, positively impacting their bottom line.

4. Market Expansion:

With the enhanced capabilities and improved product quality, ABC Textiles successfully expanded their customer base both domestically and internationally.

By investing in a non-woven embossing punching slitting and rewinding machine, ABC Textiles from the Philippines overcame multiple challenges in their production line.

Through increased automation, improved efficiency, and enhanced product quality, they were able to gain a competitive edge in the market while achieving significant cost savings.

This case study serves as an example of how advanced machinery can revolutionize manufacturing processes and deliver tangible benefits to businesses.

Nonwoven Machines Market Leader!