Disposable compressed towel machines have revolutionized the hygiene industry by offering a convenient and cost-effective solution for various applications.

![]() Price: Negotiable

Price: Negotiable

![]() Model: HBJX-400ss-S2840

Model: HBJX-400ss-S2840

![]() Power: Three-phase, 380V, 50HZ. Total installed power of a single small box:30KW

Power: Three-phase, 380V, 50HZ. Total installed power of a single small box:30KW

![]() Dimensions: Square:28*40mm, Circle:Phi45mm, Square 40*55mm,

Dimensions: Square:28*40mm, Circle:Phi45mm, Square 40*55mm,

![]() Finished Product Specifications: Finished square : 28*40 mm: the smallest size that can be produced is 19*26cm, 60 grams;

Finished Product Specifications: Finished square : 28*40 mm: the smallest size that can be produced is 19*26cm, 60 grams;

![]() Equipment Color: The default host black + aluminum alloy frame

Equipment Color: The default host black + aluminum alloy frame

![]() Raw Material: All viscose/cotton spunlace non-woven fabric, small square : 60-95g/square meter, width:

Raw Material: All viscose/cotton spunlace non-woven fabric, small square : 60-95g/square meter, width:

![]() Speed: Production speed of small squares: 380±20 pieces/min

Speed: Production speed of small squares: 380±20 pieces/min

![]() Qualified Rate: ≧97%

Qualified Rate: ≧97%

![]() Configuration: Automatic double unwind and Full servo configuration

Configuration: Automatic double unwind and Full servo configuration

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Working Voltage: 380V

Working Voltage: 380V

![]() Working Air Pressure: 6KG Air

Working Air Pressure: 6KG Air

![]() Temperature Range: 0℃-45℃

Temperature Range: 0℃-45℃

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

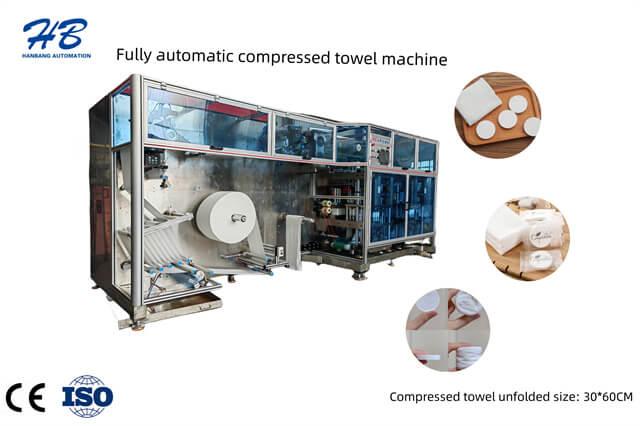

The Fully High Speed Automatic Disposable Compressed Towel Machine is a state-of-the-art device designed for efficient production of compressed towels.

With its high-speed operation, it can quickly convert regular towels into compressed form, saving space and ensuring easy transportation.

This machine is equipped with advanced technology and precision components, making it reliable and durable for long-term use.

A. MAIN PARAMETER

|

NAME/MODEL |

Fully automatic compressed towel machine (double station unwinding and automatic feeding) HBJX-400ss-S2840 |

|

Raw Material |

All viscose/cotton spun lace non-woven fabric, small square : 60-95g/square meter, width: <=320mm, maximum unwinding diameter: <=ф1000mm; |

|

Maximum and minimum specifications that can be produced |

Finished cuboid : 28*40 mm: the smallest size that can be produced is 19*26cm, 60 grams; the largest size is 28*35cm or 25*38CM |

|

POWER SUPPLY |

Three-phase, 380V, 50HZ. Total installed power of a single small box: <=35KW (including oil station)

|

|

SPEED |

Production speed of small squares: 380±20 pieces/min (according to material specifications and gram weight); acceptance standard: 28*40mm with 70-85 grams of cloth, unfolded size: 240*300mm as the |

|

FPS-- |

square: 28*40mm, the thickness of the product is subject to the sample confirmed by both parties. After the sample is confirmed, another technical supplementary agreement can be signed. |

|

DIMENSION (M) |

Length*width*height: 5.3*3*2.2m (for reference, including external gas station) |

|

COLOR |

The default host black + aluminum alloy frame. |

|

QUALIFIED RATE |

≧97%(not included wastage from the splicing and leftover material) |

|

PROPOSAL |

Automatic double unwind and Full servo configuration |

B. HBJX-400ss-S2840 Disposable Compressed Towel Machine Features:

1. High Speed Operation: The machine operates at a high speed, allowing for rapid production of compressed towels, maximizing productivity.

2. Automated Process: The entire production process is fully automated, eliminating the need for manual intervention and reducing labor costs.

3. Adjustable Compression Level: The machine offers adjustable compression levels, allowing users to customize the density of the compressed towels according to their requirements.

4. User-Friendly Interface: The machine is equipped with a user-friendly interface, making it easy to operate and monitor the production process.

5. Robust Construction: Built with high-quality materials, the machine is sturdy and durable, ensuring long-lasting performance.

1. Safety First: It is important to strictly follow the safety guidelines provided in the user manual to prevent accidents and ensure safe operation.

2. Regular Maintenance: Regular maintenance and cleaning are necessary to keep the machine in optimal condition and prolong its lifespan.

3. Operator Training: Operators should undergo proper training to understand the machine's operation and maintenance procedures.

The Fully High Speed Automatic Disposable Compressed Towel Machine finds wide application in various industries, including:

1. Hospitality: Hotels, resorts, and guesthouses can utilize compressed towels to provide convenience and hygiene to their guests.

2. Travel and Tourism: Travel agencies, airlines, and cruise ships can offer compressed towels to their customers as a compact and convenient solution for personal hygiene.

3. Sports and Fitness: Gyms, sports clubs, and fitness centers can use compressed towels to provide their members with a quick and refreshing way to clean up after workouts.

HBJX-400ss-S2840 Automatic Disposable Compressed Towel Machine Main Functions:

1. Compressing Towels: The machine effectively compresses regular towels into compact form, reducing their size for easy storage and transportation.

2. Sealing and Packaging: Once compressed, the towels are sealed and packaged automatically, ensuring their hygiene and cleanliness.

3. Customizing Density: The machine allows users to adjust the compression level, enabling them to produce compressed towels with varying degrees of softness and thickness.

4. Efficient Production: With its high-speed operation, the machine can produce a large number of compressed towels in a short period, improving overall efficiency.

How does HBJX-400ss-S2840 Compressed Towel Machine work?

1.Material unwinding system: The unwinding adopts double stations, and the power uses 2 sets of servo center-type unwinding. Equipped with automatic material receiving and storage mechanism,

the machine can receive materials without stopping during operation, and it will automatically stop and alarm when there is no material.

2. Splicing system: It adopts electric heating wire hot-melt non-woven fabric overlapping method. After the material is prepared, the equipment can automatically calculate the material splicing timing based on the unwinding meter,

and there is no need to stop the machine when switching between small rolls and large rolls.

3. Static elimination device After the material is unrolled, water passes through the nozzle atomization system or the heated wine spray atomization system to eliminate static electricity on the surface of the material to ensure the compression molding effect.

4. The Deviation Corrector is equipped with an electric eye to automatically identify the deviation corrector before and after the material is folded longitudinally to ensure that the position of the material does not shift before it enters the transverse folding.

5. Longitudinal folding device : 3 folding devices, one vertical folding device, and 2 horizontal folding devices.

6. Mold: The molding is divided into 2 sets of independent molds. Each set of molds is made of food-grade stainless steel and driven by an independent servo.

7. Control system: The whole machine is controlled by a PLC+10.5-inch touch screen electronic control system. Servo constant tension is automatically detected and processed by PLC programmable information microcomputer.

Automatic tension control between all servos can be achieved. The whole machine system is equipped with general operation rights and machine repair operation rights.

Machine repair operators can save the adjusted data to avoid misoperation by production employees. Automatic roll change can be set to a fixed number of meters, and the machine will stop automatically when the output reaches a certain level.

HBJX-300ss -R4.5 is a provide Expandable Disposable compressed towels. Finished round compressed towel machine, molding size: diameter 4.5mm: the smallest size that can b...

HBJX-160ss -R4.5 is a device designed to provide Portable Disposable Travel compressed towels. Finished product size specification: Round diameter 4.5CM....

The client, a prominent distributor of textile products in Bangladesh, aimed to enhance their manufacturing capabilities and introduce cost-effective solutions...

The compressed towel industry in Bangladeshhas experienced a significant surge in recent years, driven by the growingdemand for convenient and eco-friendly pers...

This case study presents a successfulbusiness collaboration between a prominent manufacturer of non-woven fabricsembossing machines and a client from Bangladesh...