Author:HB Nonwoven MachineryFROM:Compressed Towel Machine Manufacturer TIME:2023-11-08

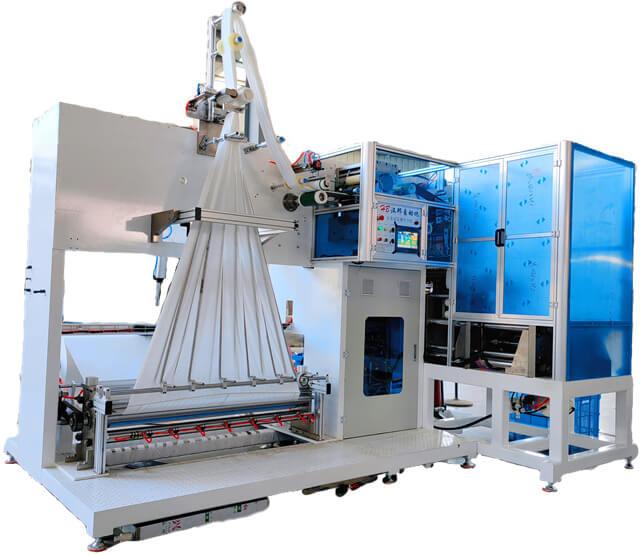

Non woven composite embossing machines play a crucial role in the production of disposable hygiene products such as diapers and sanitary napkins. These machines are designed to enhance the softness, absorption, and overall functionality of these products. However, choosing the right non woven composite embossing machine can be a daunting task, considering the wide range of options available in the market. This article aims to provide guidance on how to select the most suitable machine to meet your specific requirements.

Before investing in a non woven composite embossing machine, it is essential to identify your production capacity. This includes the number of diapers or sanitary napkins you plan to produce per hour or per day. Knowing your production capacity will help you choose a machine with the appropriate speed and efficiency to meet your demands.

The embossing pattern is a crucial factor to consider when choosing a non woven composite embossing machine. Different patterns offer various benefits in terms of softness, comfort, and absorption. It is advisable to research and understand the different types of embossing patterns available in the market and select one that aligns with your product's requirements.

The quality of materials used in a non woven composite embossing machine directly impacts the final output. It is recommended to opt for a machine that utilizes high-quality materials for enhanced durability, reliability, and longevity. Investing in a machine made from superior components can reduce maintenance costs and ensure consistent product quality.

The control system of a non woven composite embossing machine plays a vital role in its operation and ease of use. Look for machines equipped with user-friendly control panels that offer flexibility, precision, and efficiency. A well-designed control system allows for easy adjustments and minimizes the risk of errors or downtime.

Choosing a reputable manufacturer is crucial when investing in a non woven composite embossing machine. Research the manufacturer's track record, customer reviews, and industry reputation to ensure that you are purchasing a reliable and high-quality machine. A reputable manufacturer will provide excellent after-sales service, technical support, and spare parts availability.

Maintenance is an essential aspect of any machine's lifespan. Consider the maintenance requirements of the non woven composite embossing machine before making your decision. Opt for a machine that is easy to clean, inspect, and maintain. This will not only prolong the machine's life but also reduce production downtime and associated costs.

Space availability is another critical factor when selecting a non woven composite embossing machine. Measure the available floor area in your production facility and choose a machine that fits within that space. Additionally, consider the machine's configurations and accessibility requirements for maintenance and operation purposes.

Finally, it is essential to compare prices and evaluate the cost-effectiveness of the non woven composite embossing machines you are considering. While cost is a significant factor, it should not be the sole determining factor. Consider the features, quality, and long-term benefits of the machine to make an informed decision that offers the best value for your investment.

Choosing the right non woven composite embossing machine is crucial for the production of high-quality disposable hygiene products. By considering factors such as production capacity, embossing patterns, material quality, control systems, manufacturer reputation, maintenance requirements, space availability, and cost-effectiveness, you can select a machine that aligns with your specific needs. Investing in the right machine will not only improve product quality but also enhance productivity and profitability in the long run.