Author:HB Nonwoven MachineryFROM:Compressed Towel Machine Manufacturer TIME:2023-10-18

Non woven roll cutting machines are widely used in the production of diapers and sanitary napkins in the paper diaper and sanitary napkin industry. These machines play a crucial role in the manufacturing process by providing precise cutting and shaping of non-woven rolls. With their high efficiency and accuracy, non woven roll cutting machines have become an indispensable part of the industry.

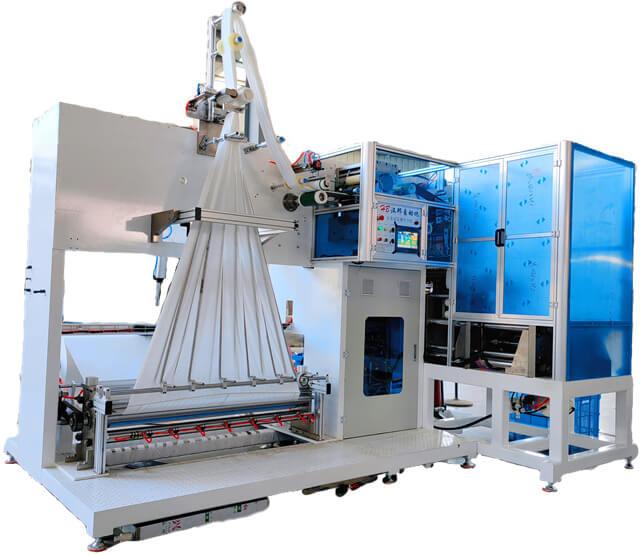

Non woven roll cutting machines are designed to cut and shape non-woven fabric rolls into desired sizes and shapes for the production of diapers and sanitary napkins. These machines are equipped with advanced technology and automated features, which enable them to achieve high precision and efficiency in cutting. They can handle a wide range of materials, including non-woven fabrics of various thicknesses and densities.

The cutting process of non woven roll cutting machines involves several steps. First, the non-woven roll is unwound and fed into the machine. Then, the machine uses rotary cutters or ultrasonic blades to cut the roll into specific lengths or shapes according to the pre-set parameters. After the cutting is complete, the machine automatically stacks the cut pieces for further processing.

Non woven roll cutting machines are known for their high efficiency. They can cut non-woven rolls at a rapid pace, ensuring maximum productivity and reducing production time. The automated features of these machines, such as auto feeding and stacking, further enhance their efficiency by minimizing manual intervention. This enables manufacturers to meet the demands of a fast-paced market.

Precision is crucial in the production of diapers and sanitary napkins. Non woven roll cutting machines excel in providing precise cutting and shaping of non-woven rolls. The advanced cutting technology used in these machines ensures clean and accurate cuts, minimizing wastage and ensuring consistent product quality. Manufacturers can rely on these machines to produce high-quality products that meet the stringent standards of the industry.

Non woven roll cutting machines offer versatility in terms of material handling and cutting options. They can handle a wide range of non-woven fabrics, including different textures, thicknesses, and densities. Additionally, these machines can be programmed to cut rolls into various shapes and sizes, allowing manufacturers to produce customized products to cater to different customer preferences.

By investing in non woven roll cutting machines, manufacturers can achieve significant cost savings. These machines improve production efficiency and reduce labor costs by automating the cutting process. Moreover, their precision cutting capabilities minimize material wastage, resulting in cost savings on raw materials. Over time, these cost savings contribute to the overall profitability of the diaper and sanitary napkin manufacturing business.

To ensure optimal performance, non woven roll cutting machines require regular maintenance and safety precautions. Manufacturers should follow the recommended maintenance schedule provided by the machine manufacturer to keep the equipment in good condition. Additionally, operators must adhere to safety protocols while operating the machines to prevent accidents and ensure a safe working environment.

Non woven roll cutting machines have revolutionized the paper diaper and sanitary napkin industry. Their high efficiency, precision cutting, versatility, and cost-saving benefits make them indispensable for manufacturers in this industry. By investing in these machines, manufacturers can streamline their production process, improve product quality, and meet the demands of a competitive market.

Non woven roll cutting machines are essential equipment in the production of diapers and sanitary napkins. They offer high efficiency, precision cutting, versatility, and cost-saving benefits. By investing in these machines and following proper maintenance and safety measures, manufacturers can enhance their production capabilities and deliver high-quality products to meet market demands.