Author:HB Nonwoven MachineryFROM:Compressed Towel Machine Manufacturer TIME:2023-10-30

Choosing the Right Non Woven Fabric Slitting Rewinding Machine

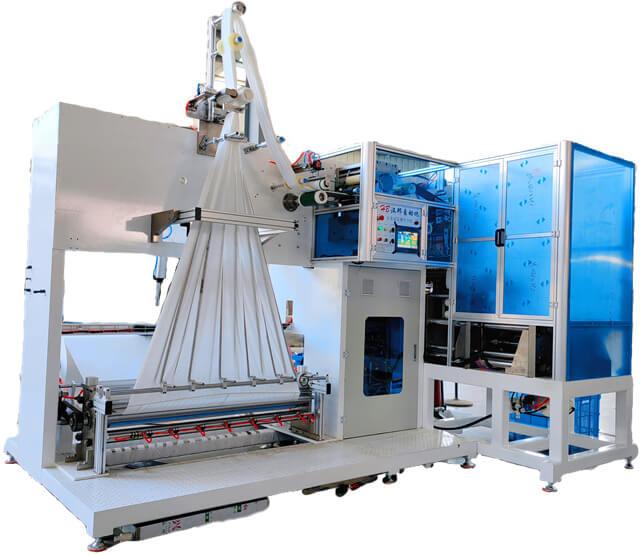

The non woven fabric industry plays a crucial role in the production of various products such as diapers and sanitary napkins. One of the essential machines in this industry is the slitting rewinding machine, which is used to process and cut large rolls of non woven fabric into smaller, more manageable rolls. Choosing the right slitting rewinding machine is vital for ensuring efficient and high-quality production. In this article, we will discuss the factors to consider when selecting a slitting rewinding machine for the non woven fabric industry.

The first factor to consider is the type of slitting rewinding machine. There are different types available, including manual, semi-automatic, and fully automatic machines. Manual machines require more labor and are suitable for small-scale operations. Semi-automatic machines offer a balance between manual and automatic operation, making them suitable for medium-sized enterprises. Fully automatic machines provide high-speed and efficient production, making them ideal for large-scale manufacturers.

Another important consideration is the slitting method used by the machine. There are various slitting methods available, such as razor blade slitting, shear slitting, and crush cutting. Razor blade slitting offers clean and precise cuts, while shear slitting is suitable for thicker fabrics. Crush cutting is effective for softer materials. Understanding the specific requirements of your non woven fabric will help determine the appropriate slitting method.

The speed and productivity of the slitting rewinding machine are crucial factors in the non woven fabric industry. Higher speed machines can significantly increase production output. However, it is essential to balance speed with the desired quality of the final product. Moreover, consider the frequency and volume of orders to ensure the machine can handle the workload efficiently.

Consider the ease of material handling when selecting a slitting rewinding machine. The machine should be able to handle different types and sizes of non woven fabric rolls effectively. Look for features such as adjustable tension control, automatic alignment, and reliable web guiding systems to ensure smooth and trouble-free operation.

Quality control is of utmost importance in the non woven fabric industry. Look for a slitting rewinding machine that incorporates advanced inspection systems to detect defects, such as uneven cuts, wrinkles, or color variations. These systems can help ensure that only high-quality rolls of non woven fabric are produced.

Regular maintenance and prompt technical support are essential for keeping the slitting rewinding machine in optimal condition. Consider machines from reputable manufacturers who provide comprehensive maintenance programs and quick response times for troubleshooting and repairs. This ensures minimal downtime and maximizes productivity.

While cost is an important factor, it should not be the sole consideration. Evaluate the long-term benefits and return on investment of the slitting rewinding machine. A high-quality machine may have a higher upfront cost but can provide greater efficiency, reliability, and longevity, resulting in improved profitability in the long run.

Consider the ease of use and training requirements for operating the slitting rewinding machine. A user-friendly machine with intuitive controls and clear documentation can reduce the learning curve for operators. Additionally, ensure that the manufacturer provides adequate training and support to ensure proper usage and maintenance of the machine.

Choosing the right non woven fabric slitting rewinding machine is crucial for the success of companies in this industry. By considering factors such as machine type, slitting methods, speed and productivity, material handling, quality control, maintenance and service, cost and return on investment, and user-friendliness, businesses can make an informed decision that maximizes efficiency and profitability. Investing in the right machine ensures consistent production of high-quality non woven fabric rolls, meeting the demands of the market and maintaining customer satisfaction.