Introduction:

This case highlights the successful implementation of a Non Woven Single Unwinding Double Rewinding Embossed Perforating Slitting Machine for a prominent baby diaper manufacturer in Turkey.

The client sought to enhance their production capabilities by investing in advanced machinery that could efficiently process and customize non-woven materials for their diapers.

Client Background:

The client, a leading baby diaper manufacturer based in Turkey, has established itself as an industry leader with a strong focus on quality and innovation. With a rapidly growing demand for their products, the company recognized the need to upgrade their manufacturing equipment to stay ahead in a highly competitive market.

Challenges Faced:

1. Inefficient Production Process: The existing slitting machine in the client's production line was outdated and struggled to meet the increasing demand for customized baby diapers.

2. Low Customization Options: The lack of embossing and Perforating features limited the client's ability to offer unique and personalized designs to their customers.

3. Inconsistent Output Quality: The inconsistent slitting precision of the old machinery resulted in product defects and increased waste, negatively impacting production efficiency and cost-effectiveness.

Solution Offered:

After carefully assessing the client's requirements, our company recommended the installation of a Non Woven Single Unwinding Double Rewinding Embossed Perforating Slitting Machine.

This advanced machinery offered several key features and benefits:

1. Enhanced Productivity: The machine's single unwinding and double rewinding systems significantly improved production speed, allowing the client to meet the growing demand for their baby diapers within shorter turnaround times.

2. Customization Capabilities: The embossing and Perforating features provided endless possibilities for creating unique and attractive designs, enabling the client to differentiate their products in the market and cater to individual customer preferences.

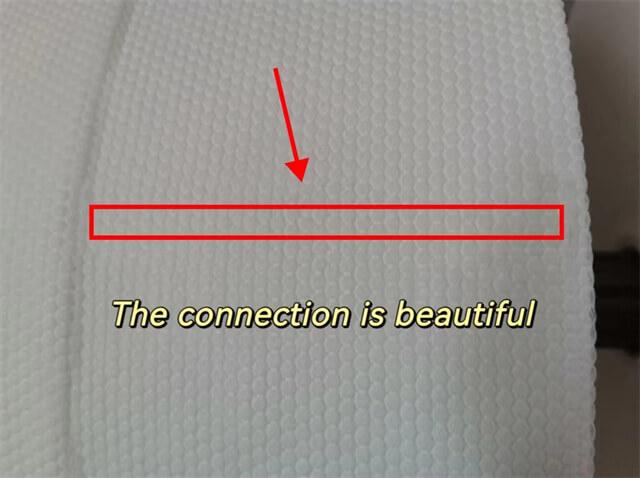

3. Precise Slitting Technology: The machine's high-precision slitting mechanism ensured consistent and accurate cuts, reducing material wastage and enhancing overall production efficiency.

4. User-friendly Interface: The machine was equipped with an intuitive interface, making it easy for operators to control and monitor the production process, minimizing the risk of errors and increasing operator productivity.

Results Achieved:

Since the implementation of the Non Woven Single Unwinding Double Rewinding Embossed Perforating Slitting Machine, the client has experienced significant improvements in their manufacturing operations:

1. Increased Production Output: The enhanced productivity of the new machinery allowed the client to meet the escalating demand for their baby diapers, resulting in a significant increase in production output.

2. Expanded Product Offering: The embossing and Perforating capabilities enabled the client to introduce a wide range of customized designs, attracting new customers and gaining a competitive edge in the market.

3. Improved Efficiency: The precise slitting technology reduced material wastage and defects, leading to improved overall production efficiency and cost-effectiveness.

4. Enhanced Customer Satisfaction: The ability to offer personalized and unique designs on baby diapers resulted in increased customer satisfaction and loyalty.

Conclusion:

The successful implementation of the Non Woven Single Unwinding Double Rewinding Embossed Perforating Slitting Machine has transformed the client's manufacturing capabilities. By upgrading their machinery, the baby diaper manufacturer in Turkey has achieved higher production output, improved efficiency, expanded product offerings, and ultimately enhanced customer satisfaction. This case highlights the importance of investing in advanced equipment to stay competitive in a rapidly evolving industry.

Nonwoven Machines Market Leader!